Modern Glass Facade Solutions

Glass facades have become a top choice for architects due to their aesthetic appeal and ability to maximize natural light. A well-designed glass facade system creates a bright and inviting indoor environment, improving both visual appeal and occupant comfort.

At Arad Steel, we specialize in high-quality stainless steel fittings for spider and clamp glass facade systems. Our custom-engineered solutions ensure structural integrity, durability, and modern design at a competitive price.

Head Office Address:

Tehran, Kilometer 2, Fath Highway, Iran Elevator Trade Center, 3rd Floor, Office Unit 301

Showroom Address:

Tehran, Kharrazi Highway, Iran Mall, Almas Entrance, G0 Floor, Tavana Building Materials Hypermarket

Types of Glass Facades

Glass facades are one of the most innovative and aesthetically appealing exterior solutions for commercial and residential buildings. Different installation techniques and support structures create unique designs while ensuring structural stability and energy efficiency. Below are the most common types of glass facade systems with a detailed explanation of their features and benefits.

Glass Facade with Stainless Steel Fittings

In this type of facade, stainless steel connectors secure glass panels to the supporting structure, which may consist of:

✔ Steel or aluminum profiles

✔ Glass fins

✔ Cable systems

The primary stainless steel fittings used in these facades are:

✔ Spider fittings – Allow point-fixed connections, commonly used in frameless glass facades.

✔ Clamp fittings – Offer a cost-effective alternative to spider fittings, used for securing glass panels.

Spider Glass Facade with Steel Tubes or Profiles

The most cost-effective and widely used system, where spider fittings connect glass panels to a supporting framework made of:

✔ Steel tubes or rectangular profiles (material and thickness vary based on project requirements).

✔ Provides excellent load-bearing capacity while maintaining a modern aesthetic.

✔ Advantages:

✅ Affordable & widely used solution

✅ Compatible with large glass panels

✅ Highly customizable for different projects

Fin Glass Facade (Glass Fin System)

In this frameless glass facade, structural glass fins (vertical glass blades) serve as load-bearing supports, eliminating the need for metal profiles.

✔ Key Features:

✔ Made of laminated tempered glass (typically three layers of 10mm glass).

✔ Glass fins are fully transparent, enhancing openness and natural light penetration.

✔ Customizable glass fin width depending on structural and design requirements.

✔ Advantages:

✅ Minimalist and seamless design

✅ No obstructive metal elements

✅ Ideal for high-end commercial and luxury projects

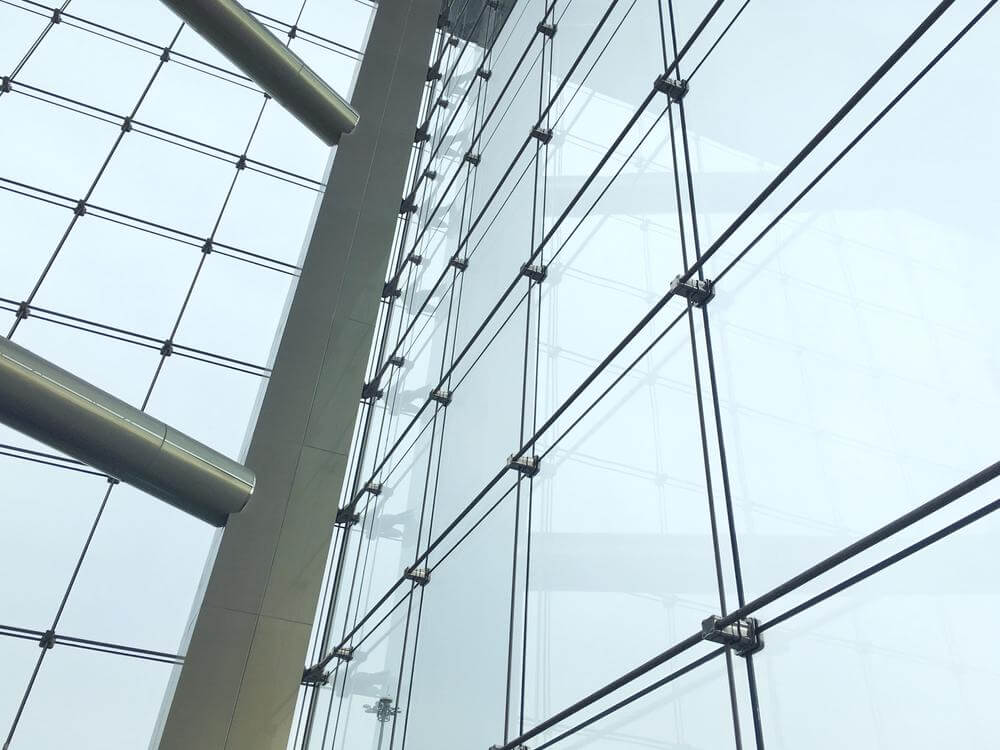

Cable Tension Glass Facade (Suspended Glass System)

This high-tech glass facade system uses stainless steel cables or tension rods to transfer loads to the building structure. It offers exceptional transparency with minimal visible hardware.

There are two primary types of cable-supported glass facades:

? Cable Net Glass Facade

✔ Uses a network of vertical and horizontal cables to support glass panels.

✔ Minimizes the use of metal frames, maximizing transparency and aesthetics.

✔ Glass panels appear to "float," creating a modern and lightweight effect.

? Tension Rod Glass Facade

✔ Relies on stainless steel tension rods to stabilize the facade.

✔ Provides a clean, high-tech appearance while maintaining high structural integrity.

✔ Advantages:

✅ Maximum transparency & lightweight design

✅ Reduces visible metal components

✅ Ideal for airports, commercial towers, and retail centers

Curtain Wall Glass Facade (Unitized & Stick Systems)

Curtain wall systems consist of glass panels mounted on an aluminum framework, providing both thermal and structural benefits.

✔ Unitized Curtain Wall:

- Prefabricated panels assembled off-site, ensuring fast installation and reduced labor costs.

- Ideal for high-rise buildings and large-scale projects.

✔ Stick Curtain Wall:

- Assembled on-site, offering greater design flexibility.

- Common in medium-rise commercial and residential buildings.

✔ Advantages:

✅ Improved insulation (thermal & acoustic performance)

✅ High resistance to wind and weather conditions

✅ Suitable for high-rise and commercial buildings

Structural & Thermal Design Calculations for Glass Facades

A well-designed glass facade must meet structural, thermal, and acoustic performance requirements while maintaining aesthetics, safety, and energy efficiency. Below are key considerations in glass facade design and analysis:

Structural Analysis

Glass facades must withstand various external forces and loads, including:

✔ Wind Loads: Calculated based on building height, location, and climate conditions to prevent excessive deflection.

✔ Seismic Loads: In earthquake-prone areas, flexibility and structural reinforcement are critical.

✔ Dead & Live Loads: The weight of glass panels, fittings, and environmental forces must be considered.

✅ Structural Stability Requirement: Deflection and movement must remain within acceptable limits to prevent failure or damage.

Thermal Performance Analysis

✔ U-Value Calculation: Measures heat transfer rate through glass; a lower U-Value indicates better insulation.

✔ Solar Heat Gain Coefficient (SHGC): Determines how much solar heat the glass absorbs or reflects.

✔ Low-E Glass Coatings: Reflect infrared radiation while allowing visible light to pass, improving energy efficiency.

✔ Double & Triple Glazing: Traps air or gas (such as Argon or Krypton) between layers, reducing heat transfer and improving thermal insulation.

✔ Solar Control Glass (Sunergy Glass): Reduces excessive solar heat gain, minimizing the need for air conditioning.

✅ Thermal Efficiency: A properly designed glass facade reduces heating & cooling costs, enhancing energy efficiency.

Acoustic Performance (Noise Reduction)

✔ Sound Transmission Class (STC) Rating: Evaluates sound insulation properties of glass.

✔ Laminated Glass for Soundproofing: PVB interlayers absorb sound waves, reducing noise pollution.

✔ Gas-Filled Insulated Glass Units (IGU): Replacing air with SF6 gas between double glazing significantly improves soundproofing but increases costs.

✅ Best Acoustic Solution: Laminated double glazing is cost-effective while providing high noise reduction efficiency.

Advantages of Glass Facades

1️⃣ Aesthetic Appeal & Design Flexibility

Glass facades transform the visual appeal of buildings, offering modern aesthetics and unique design flexibility. With a wide range of glass colors and finishes, architects can create distinctive and elegant facades.

✔ Gives identity to the building

✔ Modern & sleek appearance

✔ Customizable with different glass colors & coatings

2️⃣ Unobstructed & Transparent Views

Glass facades allow seamless indoor-outdoor connectivity, enhancing the visual experience while maintaining safety and efficiency.

✔ Maximizes visibility

✔ Creates a sense of openness in commercial spaces

3️⃣ Natural Light Transmission

Glass allows up to 80% light penetration, reducing the need for artificial lighting and enhancing occupant well-being.

✔ Energy-efficient & reduces electricity consumption

✔ Creates a bright and comfortable indoor environment

✔ Adds real estate value

4️⃣ Structural Weight Reduction

Glass facades are lighter than traditional materials, reducing overall building weight.

✔ 20-40% weight reduction in commercial buildings

✔ 15-30% weight reduction in residential buildings

✔ Enhances structural efficiency & cost-effectiveness

5️⃣ Acoustic Insulation (Noise Reduction)

Double-glazed and laminated glass can significantly reduce noise pollution.

✔ Laminated glass absorbs sound waves using PVB interlayers

✔ Filling the gap between double glazing with SF6 gas enhances noise reduction

6️⃣ Thermal Insulation & Energy Efficiency

✔ Low-E Glass: Reflects infrared radiation while allowing visible light to pass through, reducing heat loss in winter & heat gain in summer.

✔ Solar Control Glass (Sunergy Glass): Blocks excess solar heat, maintaining indoor comfort without excessive cooling needs.

✔ Double & Triple Glazing: Argon or Krypton gas-filled units act as an insulating barrier, preventing heat transfer.

✔ U-Value Optimization: Lower U-values indicate better thermal performance.

✔ Benefits:

- Reduces HVAC costs

- Maintains comfortable indoor temperatures

- Improves energy efficiency

7️⃣ Low Maintenance & Durability

Glass facades offer long-term durability, resisting weather conditions, UV rays, and corrosion.

✔ Self-cleaning coatings minimize maintenance needs

✔ Scratch-resistant glass extends lifespan

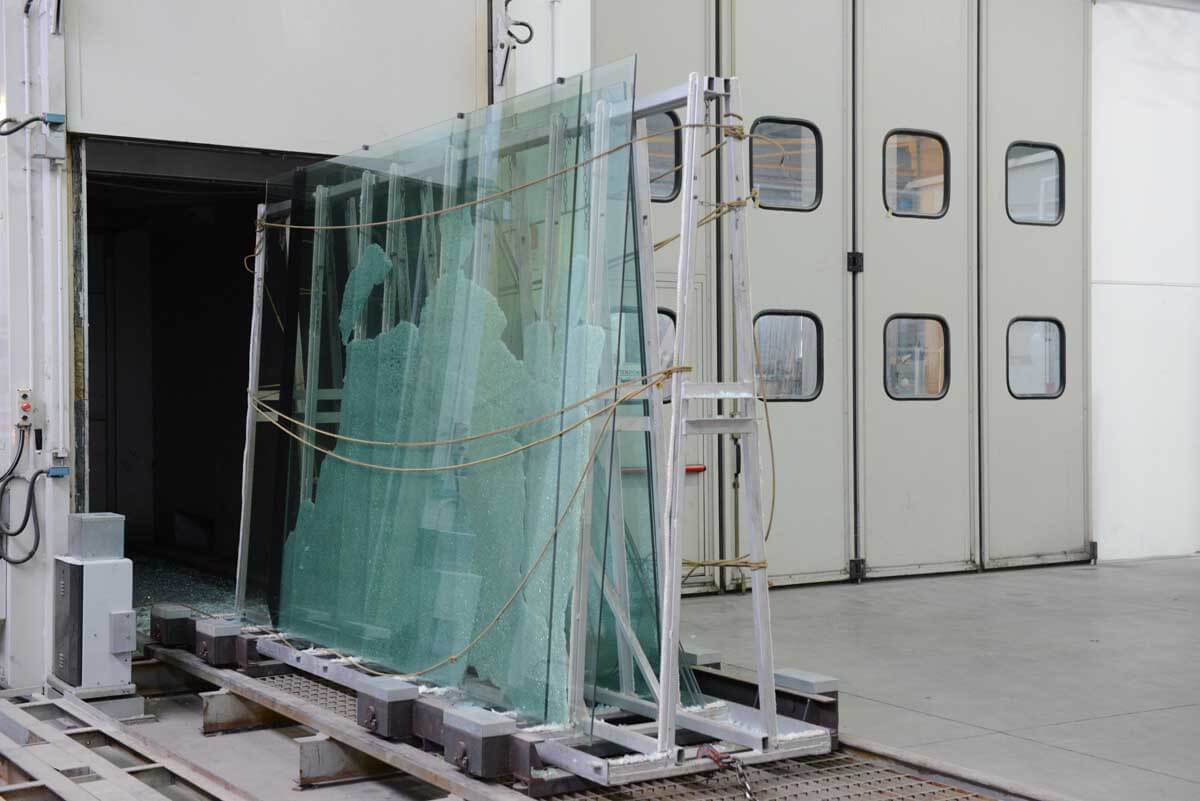

8️⃣ Safety & Preventing Spontaneous Glass Breakage

✔ Heat Soak Testing (HST): Prevents Nickel Sulfide Inclusion (NiS) defects in tempered glass by heating it to 280°C for 2-4 hours, eliminating weak glass before installation.

✔ Laminated Glass: Enhances safety by keeping glass shards intact upon breakage.

✔ Semi-Tempered Glass Alternative: Suitable for high-rise buildings to reduce risks.

Factors Determining the Cost of Glass Facade Installation

1️⃣ Type of Glass Facade System

The installation method and required structural components significantly impact the total cost. Each glass facade system (e.g., spider glass, cable-supported, fin glass, or curtain wall) requires different fittings, materials, and installation techniques, influencing pricing.

✔ Spider Glass Facades: Requires stainless steel spiders & tension fittings, making it costlier but highly durable.

✔ Cable-Supported Facades: Needs high-strength cables & tension rods, adding engineering complexity but reducing visible support elements.

✔ Fin Glass Facades: Uses laminated glass fins for support, increasing glass thickness & production costs.

✔ Curtain Wall Systems: Aluminum framing & double-glazing contribute to higher material & installation expenses.

2️⃣ Type & Thickness of Glass

✔ Glass Type: Tempered, laminated, low-E, insulated, or double-glazed glass – each has a different cost structure.

✔ Glass Thickness: Thicker glass (e.g., 8mm, 10mm, 12mm, or laminated configurations) increases material & production costs.

✔ Jumbo Size or Custom Glass Panels: Larger or special-sized panels require higher manufacturing precision, increasing costs.

3️⃣ Structural & Connection Elements

✔ Material of Support Structures: Stainless steel (SS 304 & SS 316), aluminum, or steel directly affects cost.

✔ Fittings & Connectors: High-quality clamps, brackets, and bolts in spider, fin, or cable facades vary in pricing.

✔ Custom vs. Standard Hardware: Custom-engineered connectors & brackets add extra costs compared to off-the-shelf solutions.

4️⃣ Installation Complexity & Labor Costs

✔ Height & Accessibility: High-rise buildings require special equipment & safety measures, increasing labor costs.

✔ Engineering & Structural Analysis: Calculating wind loads, seismic forces, and thermal expansion can add costs for design validation.

✔ Customization Requirements: Unique shapes, curved glass, or special coatings increase installation time & cost.

Last News

Spotlight on Aradsteel's Showcase: Highlights from Gilan Construction Exhibition 2024

Dive into Aradsteel's standout presence at the Gilan Construction Exhibition 2024, where we unveiled our latest innovations in steel fittings and cutting-edge glass-steel architectural systems. Explore how our solutions are reshaping the future of construction with durability, aesthetic appeal, and versatile applications for both residential and commercial projects.

Read more